Specification

| Parameter | Description |

|---|---|

| Material | Aluminum |

| Alloy | Various, including 6061, 5052, 3003, and more |

| Thickness | 2-3mm (0.079-0.118 inches) |

| Size | Typically available in standard sheet sizes |

| Surface Finish | Mill finish (unpolished) or custom finishes available |

| Weight per Square Meter | Approximately 1.35-2.7 kg (2.97-5.9 lbs) |

| Tensile Strength | Varies based on alloy and temper |

| Corrosion Resistance | Excellent |

| Weldability | Good |

| Machinability | Varies based on alloy |

| Common Uses | General sheet metal work, fabrication, automotive panels, signage, and more |

| Availability | Widely available through suppliers |

| Customization Options | Available for alloy, surface finish, and size |

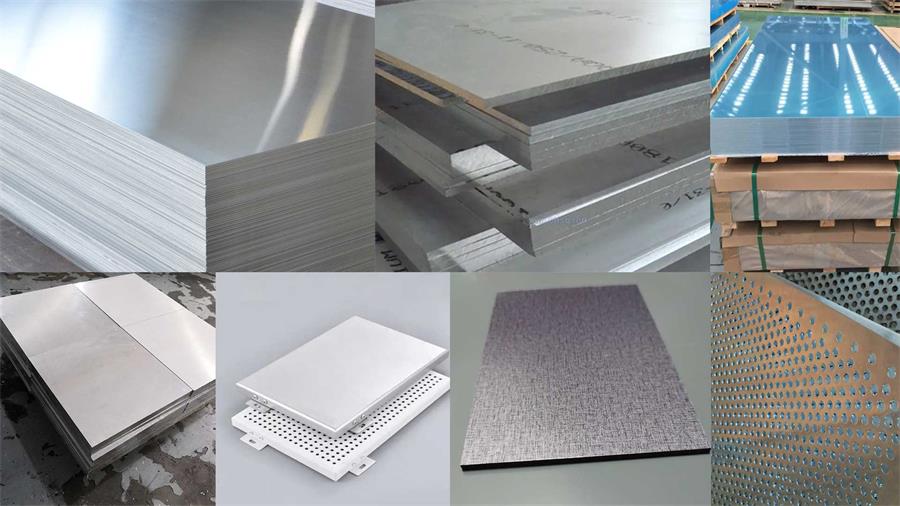

Features of 2-3mm Aluminium Plate:

- Lightweight: Aluminum is inherently lightweight, making it ideal for applications where weight is a concern.

- Corrosion Resistance: Aluminum forms a protective oxide layer, enhancing its resistance to corrosion and rust.

- Machinability: Aluminum is relatively easy to machine and fabricate to meet specific design requirements.

- Weldability: It can be welded using various techniques, offering flexibility in assembly.

- Strength: Despite its lightness, aluminum plates in this thickness range offer good structural strength.

- Recyclable: Aluminum is highly recyclable, contributing to sustainability efforts.

Applications of 2-3mm Aluminium Plate:

- Automotive Components: Used for manufacturing automotive parts like body panels, trim, and engine components due to its lightweight and corrosion resistance.

- Electronics: Commonly employed in electronic enclosures, heat sinks, and printed circuit boards (PCBs) for its heat dissipation properties.

- Aerospace: Used in aircraft interiors, structural elements, and components due to its lightweight strength.

- Signage: Ideal for making durable and lightweight signs and billboards for both indoor and outdoor use.

- Marine Industry: Utilized for boat building, hulls, and components due to its resistance to saltwater corrosion.

- Model Making: Popular for hobbyist and professional model making due to its ease of machining and shaping.

- Construction: Used in architectural elements like decorative panels, cladding, and facades due to its corrosion resistance and aesthetic appeal.

- General Fabrication: Versatile for a wide range of custom fabrication projects, including brackets, frames, and support structures.

- Packaging: Utilized for packaging and containers in the food and pharmaceutical industries due to its hygienic properties.

- Solar Energy: Used for solar panel framing and support structures in renewable energy systems.

- Transportation: In the transportation industry, it’s used for manufacturing trailers, truck bodies, and railcars due to its lightweight and durability.

- Sports Equipment: Found in various sports equipment like bicycle frames and sporting goods due to its lightness.

- Craftsmanship: Popular for crafting and artistic projects due to its ease of handling and ability to take on various finishes.

The 2-3mm aluminium plate’s combination of characteristics, including lightweight, corrosion resistance, and versatility, makes it suitable for a wide range of applications across industries.

Common Alloy Grades of 2-3mm Aluminum Plate

- 6061 Aluminum Plate (2-3mm):

- Characteristics: Offers a balance of strength, corrosion resistance, and weldability. Excellent machinability.

- Applications: Aerospace components, marine parts, automotive panels, and general structural elements.

- 5052 Aluminum Plate (2-3mm):

- Characteristics: High resistance to corrosion, good formability, and weldability.

- Applications: Marine applications, vehicle panels, signage, and architectural elements.

- 3003 Aluminum Plate (2-3mm):

- Characteristics: Good formability, moderate strength, and corrosion resistance.

- Applications: General-purpose sheet metal work, decorative elements, and HVAC components.

- 5083 Aluminum Plate (2-3mm):

- Characteristics: Exceptional corrosion resistance, high strength, and weldability.

- Applications: Marine industry, shipbuilding, offshore structures, and armor plating.

- 2014 Aluminum Plate (2-3mm):

- Characteristics: High strength, heat treatable, and good machinability.

- Applications: Aerospace fittings, hydraulic systems, and structural components.

- 6013 Aluminum Plate (2-3mm):

- Characteristics: Excellent formability and weldability, good strength.

- Applications: Automotive panels, body structures, and general fabrication.

- 7075 Aluminum Plate (2-3mm):

- Characteristics: High strength, excellent machinability, and good corrosion resistance.

- Applications: Aerospace, military equipment, and high-stress structural parts.

- 2024 Aluminum Plate (2-3mm):

- Characteristics: High strength-to-weight ratio and excellent fatigue resistance.

- Applications: Aircraft skins, structural components, and fasteners.

- 7072 Aluminum Plate (2-3mm):

- Characteristics: High corrosion resistance, particularly in saltwater environments.

- Applications: Marine equipment, boat hulls, and seawater desalination.

- 2025 Aluminum Plate (2-3mm):

- Characteristics: High strength, fatigue resistance, and excellent weldability.

- Applications: Aerospace and automotive structural components, military equipment.

These aluminum alloy grades offer a range of properties, allowing you to select the most suitable one based on your project’s requirements, whether it’s for strength, corrosion resistance, machinability, or other specific characteristics.

How to choose 2-3mm Aluminum Plate?

Choosing the right 2-3mm aluminum plate for your specific project involves considering several key factors to ensure it meets your requirements. Here’s a step-by-step guide to help you make an informed decision:

- Identify Your Application:

- Determine the purpose of the aluminum plate. Is it for structural support, marine use, aerospace, automotive, or another application? Knowing the application specifics will guide your selection.

- Define Your Requirements:

- Outline the critical properties you need, such as strength, corrosion resistance, formability, and weldability. Make a list of must-have characteristics.

- Consider Alloy Grade:

- Different alloy grades offer various properties. Consult with your supplier or manufacturer to choose an alloy that matches your requirements. Common choices include 6061, 5052, 5083, and more.

- Evaluate Thickness:

- Determine the ideal thickness for your application. A 2-3mm aluminum plate is your choice, but other thicknesses may also be available.

- Assess Surface Finish:

- Decide whether you need a specific surface finish, such as polished or mill finish, depending on your project’s aesthetic and functional requirements.

- Budget Consideration:

- Consider your budget constraints. Some alloy grades may be more cost-effective than others, so balance your requirements with the available budget.

- Environmental Factors:

- Evaluate the environment in which the aluminum plate will operate. If it will be exposed to harsh conditions, prioritize corrosion resistance and durability.

- Customization Needs:

- Determine if you require customized sizes, shapes, or additional processing, as some suppliers offer these services.

- Supplier Reputation:

- Choose a reputable supplier or manufacturer with a track record of delivering high-quality aluminum plates and good customer support.

In conclusion, the choice between a 2mm or 3mm aluminum plate depends on the specific needs of your project and its intended application. Both thicknesses offer a range of benefits, including lightweight construction, corrosion resistance, and versatility. When selecting the appropriate thickness, it’s essential to consider factors such as structural requirements, weight constraints, and environmental conditions.

A 2mm aluminum plate may be preferable for applications where weight reduction is crucial or where the material needs to be more pliable for shaping. On the other hand, a 3mm aluminum plate provides slightly greater strength and rigidity, making it suitable for applications demanding structural integrity.

Ultimately, the right choice should align with your project’s unique specifications and performance criteria. By carefully evaluating your needs, consulting with experts, and considering the properties of different alloy grades, you can confidently select the 2mm or 3mm aluminum plate that best suits your project, ensuring its success and longevity.

or Leave a message online in the form