Specification

| Property | Value |

|---|---|

| Alloy Type | 7075 |

| Temper | T6, T651, T6511, or custom temper |

| Thickness | Varies (0.2-300mm) |

| Width | Varies (typically up to 48″ or 1219.2 mm) |

| Length | Varies (typically up to 144″ or 3657.6 mm) |

| Density | 2.81 g/cm³ |

| Tensile Strength | 74,000 – 78,000 psi |

| Yield Strength | 63,000 – 69,000 psi |

| Elongation at Break | 5 – 11% |

| Modulus of Elasticity | 71.7 x 10^6 psi |

| Thermal Conductivity | 130 W/m·K |

| Electrical Conductivity | 18% IACS |

| Melting Point | 480°C (900°F) |

| Hardness (Brinell) | 150 – 160 |

| Machinability | Fair to Poor |

| Weldability | Fair |

| Corrosion Resistance | Good (not as corrosion-resistant as some other alloys) |

| Formability | Poor (limited formability compared to softer alloys) |

| Finish | Mill finish, brushed, anodized, or painted |

Details of 7075 Aluminum Plate

| Element | Percentage Composition |

|---|---|

| Silicon (Si) | 0.4% max |

| Iron (Fe) | 0.5% max |

| Copper (Cu) | 1.2 – 2.0% |

| Manganese (Mn) | 0.3% max |

| Magnesium (Mg) | 2.1 – 2.9% |

| Chromium (Cr) | 0.18 – 0.28% |

| Zinc (Zn) | 5.1 – 6.1% |

| Titanium (Ti) | 0.2% max |

| Other Elements | 0.05% each, 0.15% total max |

| Aluminum (Al) | Remaining balance |

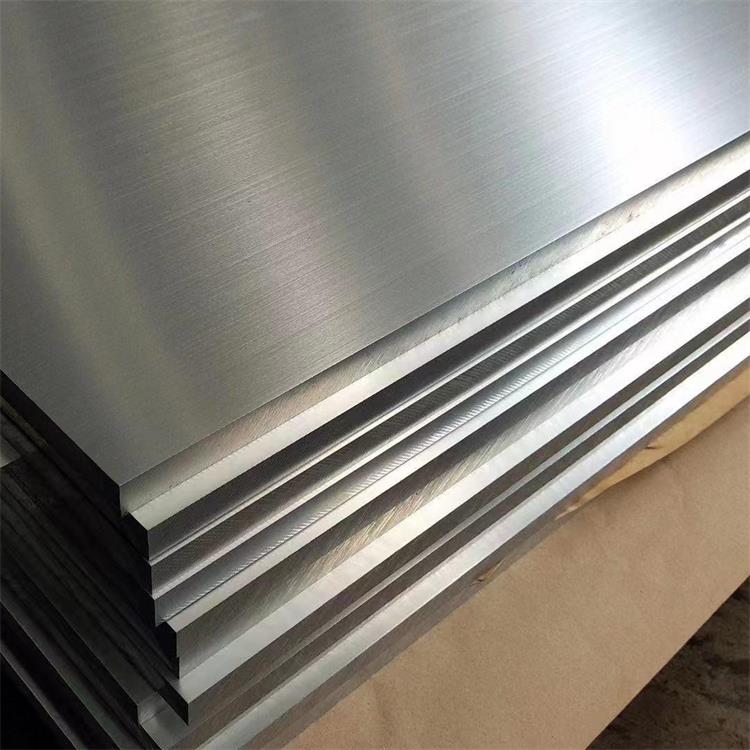

7075 aluminum sheet is a high-strength alloy known for its excellent mechanical properties, making it a preferred choice in various industries. Here are its key features, uses, and benefits:

Features:

- High Strength: 7075 aluminum sheet exhibits exceptional strength, comparable to many steel alloys. It offers impressive tensile and yield strength, making it suitable for demanding applications.

- Lightweight: Despite its high strength, 7075 aluminum is relatively lightweight. This characteristic is advantageous in industries where weight reduction is critical, such as aerospace and automotive.

- Excellent Fatigue Resistance: It has excellent fatigue resistance, making it suitable for components subjected to cyclic loading and stress, such as aircraft parts.

- Good Corrosion Resistance: While not as corrosion-resistant as some other aluminum alloys, it still offers reasonable corrosion resistance and is often used in applications where strength is a primary consideration.

- Machinability: It can be machined with relative ease compared to some other high-strength materials, making it suitable for precision machining operations.

Uses:

- Aerospace: 7075 aluminum is commonly used in the aerospace industry for structural components such as aircraft fuselage frames, wing spars, and landing gear components due to its high strength-to-weight ratio.

- Automotive: It finds applications in the automotive sector for performance and racing parts, where the combination of strength and weight reduction is crucial.

- Defense: The alloy is used in military and defense applications for its strength and durability, including armored vehicles and weapon systems.

- Sports Equipment: 7075 aluminum is employed in the production of sports equipment like bicycle frames, rock climbing gear, and baseball bats due to its high strength and lightweight properties.

- High-Performance Machinery: It’s used in high-performance machinery, including CNC machines and robotics, where precision and strength are vital.

Benefits:

- High Strength: 7075 aluminum’s exceptional strength-to-weight ratio allows for the design of robust and lightweight structures.

- Lightweight: Its lightweight nature reduces fuel consumption in transportation and improves overall efficiency.

- Fatigue Resistance: Excellent fatigue resistance ensures the longevity of components subjected to repetitive stress.

- Machinability: Relative ease of machining simplifies the manufacturing process and lowers production costs.

- Versatility: 7075 aluminum’s versatility allows it to be used in various high-stress applications across industries.

- Durability: It offers durability and longevity, reducing maintenance and replacement costs.

In summary, 7075 aluminum plate is valued for its exceptional strength, lightweight properties, and resistance to fatigue. Its high-performance characteristics make it a preferred material in industries such as aerospace, automotive, and defense, where both strength and weight considerations are paramount.

How Much Does 7075 T6 Aluminum Sheet Cost Per Kilogram

The price of Xienuo’s 7075 t6 aluminum plates is about US$2.0-4.0 per kilogram. The simple calculation method is the price of one kilogram of aluminum ingots plus the processing cost per kilogram. The price of aluminum plates is affected by the price fluctuation of aluminum ingots and processing costs, and will also follow changes in market conditions.

How to Choose 7075 Aluminum Sheet for Your Project

- Define Requirements: Clearly outline the required size, thickness, and specific mechanical properties needed (strength, durability).

- Select Alloy and Temper: Confirm that 7075 alloy and the appropriate temper (T6, T651, etc.) suit your application’s requirements.

- Consider Surface Finish: Decide on the finish (mill finish, anodized, or painted) based on functionality and aesthetics.

- Assess Corrosion Needs: Evaluate your project’s exposure to corrosion and determine if 7075’s corrosion resistance meets your requirements.

- Review Supplier Options: Research reputable aluminum suppliers based on quality, pricing, and services offered.

- Budget Considerations: Align the cost of 7075 aluminum with your project budget.

- Compliance with Standards: Ensure the selected aluminum sheet meets industry or regulatory standards, especially for specialized applications.

- Seek Expert Advice: Consult experts or engineers if uncertain about material selection or specific requirements.

Why Opt for Our 7075 Aluminum Sheet

- High-Quality Material: Our 7075 aluminum sheets are made from top-grade materials, ensuring durability and performance.

- Precision Manufacturing: We employ precise manufacturing techniques and strict quality control to meet the highest industry standards.

- Customization: We offer a wide range of sizes, thicknesses, and custom options to meet your project’s specific requirements.

- High Strength: Our 7075 sheets provide exceptional strength, ideal for demanding applications.

- Lightweight: Despite its strength, our sheets are lightweight, reducing overall project weight and enhancing efficiency.

- Durability: 7075 aluminum offers durability and longevity, reducing maintenance and replacement costs.

- Expertise: With our experience, we provide expert advice to help you choose the right product for your project.

- Competitive Pricing: We offer competitive prices without compromising on quality, providing value for your investment.

- Wide Range of Applications: Our 7075 aluminum sheets are versatile and suitable for various industries and applications.

- Customer Satisfaction: Your satisfaction is our priority. We focus on delivering quality products and excellent service to meet your project needs.