Specification

| Property | Value |

|---|---|

| Alloy Type | 6061 |

| Temper | T6 |

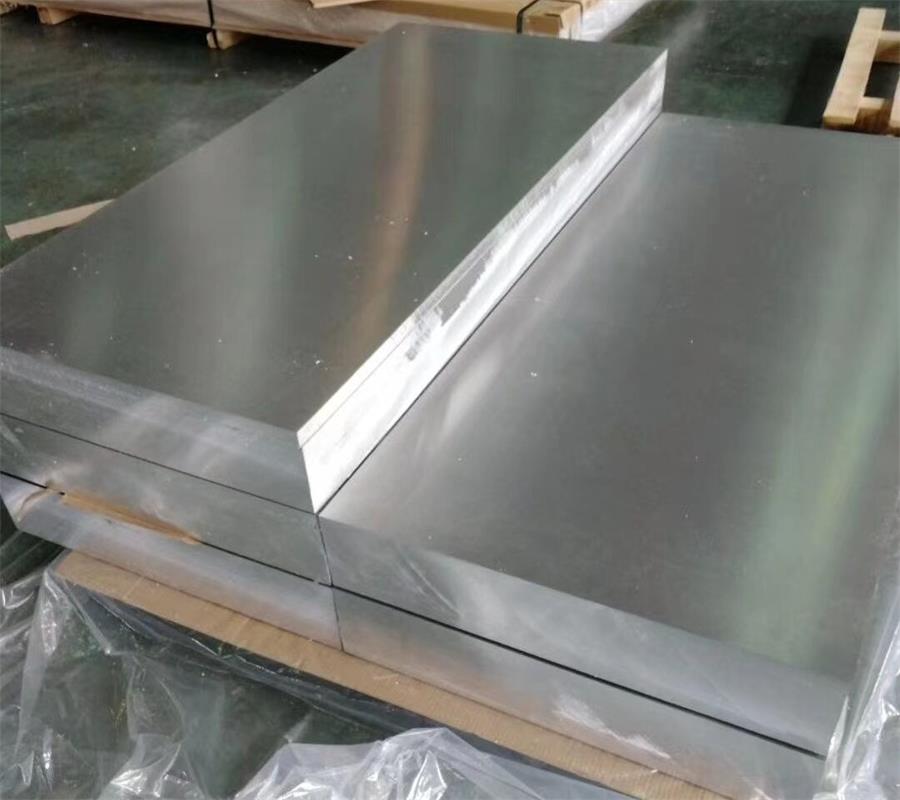

| Thickness | Varies (1.5-30.0mm) |

| Width | Varies (typically up to 48″ or 1219.2 mm) |

| Length | Varies (typically up to 144″ or 3657.6 mm) |

| Density | 2.70 g/cm³ |

| Tensile Strength | 45,000 – 55,000 psi |

| Yield Strength | 40,000 – 50,000 psi |

| Elongation at Break | 12 – 17% |

| Modulus of Elasticity | 10.0 x 10^6 psi |

| Thermal Conductivity | 167 W/m·K |

| Electrical Conductivity | 40% IACS |

| Melting Point | 582°C (1,080°F) |

| Hardness (Brinell) | 95 |

| Machinability | Good |

| Weldability | Excellent |

| Corrosion Resistance | Good (in most environments) |

| Formability | Good |

| Finish | Mill finish, brushed, anodized, or painted |

It’s always important to refer to the manufacturer’s data sheets and specifications for precise information when working with this material.

Details of 6061 t6 Aluminum Sheet

| Element | Percentage Composition |

|---|---|

| Silicon (Si) | 0.40 – 0.8% |

| Iron (Fe) | 0.70% max |

| Copper (Cu) | 0.15 – 0.40% |

| Manganese (Mn) | 0.15% max |

| Magnesium (Mg) | 1.0 – 1.2% |

| Chromium (Cr) | 0.04 – 0.35% |

| Zinc (Zn) | 0.25% max |

| Titanium (Ti) | 0.15% max |

| Other Elements | 0.05% each, 0.15% total max |

| Aluminum (Al) | Remaining balance |

6061-T6 aluminum sheet is a versatile and widely used material known for its excellent strength, corrosion resistance, and a wide range of applications. Here’s a detailed description of its features, uses, and advantages:

Features:

- High Strength: 6061-T6 aluminum sheet offers a high tensile strength, making it suitable for applications that require structural integrity and load-bearing capabilities.

- Corrosion Resistance: This alloy has good corrosion resistance, making it suitable for outdoor and marine applications. It forms a protective oxide layer on the surface that prevents further corrosion.

- Weldability: 6061-T6 is highly weldable, allowing for various fabrication techniques, including welding, brazing, and soldering, to create complex structures and components.

- Machinability: It is relatively easy to machine, making it suitable for precision machining operations such as milling, drilling, and turning.

- Formability: The alloy can be easily formed and bent without cracking, which is useful for applications requiring complex shapes or curved surfaces.

- Heat Treatable: The “T6” temper designation indicates that the alloy has undergone a heat treatment process, which further enhances its mechanical properties, including strength.

Uses:

- Aerospace: 6061-T6 aluminum is commonly used in aircraft and aerospace applications for its lightweight properties, high strength, and corrosion resistance. It is used for aircraft frames, wing components, and structural parts.

- Automotive: In the automotive industry, this alloy is used for components like wheels, suspension parts, and chassis components due to its strength-to-weight ratio and durability.

- Marine: Its corrosion resistance makes it a preferred choice for marine applications such as boat hulls, masts, and other structural components.

- Construction: 6061-T6 is used in the construction industry for scaffolding, structural framing, and architectural elements where strength and corrosion resistance are required.

- Electronic Enclosures: It is commonly used for electronic enclosures and housings due to its electrical conductivity and ability to dissipate heat.

- Sports Equipment: Bicycle frames, golf club heads, and other sports equipment benefit from the alloy’s lightweight and strong properties.

- Industrial Components: This aluminum alloy is employed in various industrial applications, including conveyor systems, heat exchangers, and hydraulic systems.

Advantages:

- High Strength-to-Weight Ratio: Its high strength and relatively low density result in an excellent strength-to-weight ratio, making it suitable for lightweight yet strong structures.

- Corrosion Resistance: The alloy’s resistance to corrosion means it can withstand exposure to harsh environments and reduces maintenance requirements.

- Versatility: 6061-T6 is versatile and can be used for a wide range of applications due to its combination of properties.

- Weldability: It is easy to weld, allowing for the creation of complex assemblies and structures.

- Heat Treatable: The T6 temper enhances its mechanical properties, providing even greater strength and hardness when needed.

- Cost-Effective: Compared to some other high-strength materials, 6061-T6 aluminum is often more cost-effective, making it a popular choice for many industries.

Overall, 6061-T6 aluminum sheet is a favored material in various industries due to its impressive combination of strength, corrosion resistance, and versatility, making it suitable for a wide range of applications.

How Much Does 6061 T6 Aluminum Plate Cost Per Kilogram

The price of Xienuo manufacturer’s aluminum plates is about US$2.4-3.6 per kilogram. The simple calculation method is the price of one kilogram of aluminum ingots plus the processing cost per kilogram. The price of aluminum plates is affected by the price fluctuation of aluminum ingots and processing costs, and will also follow changes in market conditions.

How to Choose 6061 t6 Aluminum Sheet for Your Project

Choosing the right 6061-T6 aluminum sheet for your project involves considering several key factors to ensure that the material meets your specific requirements and performs optimally. Here are the steps to help you select the appropriate 6061-T6 aluminum sheet for your project:

1. Determine Project Requirements:

- Define the purpose and function of the aluminum sheet within your project.

- Consider factors such as load-bearing capacity, corrosion resistance, formability, and appearance requirements.

2. Identify Thickness and Size:

- Measure or calculate the required thickness and dimensions of the aluminum sheet based on your project’s design and structural requirements.

- Ensure the selected sheet size is readily available or can be custom ordered if necessary.

3. Consider Temper:

- 6061-T6 is a specific temper designation that indicates the material has been heat-treated to enhance its strength.

- Verify if the T6 temper is suitable for your project’s strength and hardness requirements.

- If different temper properties are needed, such as improved formability (T4) or maximum strength (T651), consider those options.

4. Evaluate Surface Finish:

- Decide if you require a specific surface finish, such as mill finish, brushed, anodized, or painted, based on your project’s aesthetic and functional needs.

5. Check Alloy Purity:

- Ensure that the aluminum sheet is 6061 alloy and not a different aluminum alloy.

- Check for any specific alloy purity requirements, especially if your project has strict material specifications.

6. Assess Corrosion Resistance:

- Consider the environmental conditions the aluminum sheet will be exposed to, such as humidity, saltwater, or chemicals.

- Confirm that 6061-T6’s inherent corrosion resistance meets your project’s durability needs. Additional corrosion protection treatments may be necessary in corrosive environments.

7. Review Supplier Options:

- Research reputable aluminum suppliers and manufacturers.

- Compare prices, lead times, and available services such as cutting, shearing, or custom fabrication.

- Ensure that the supplier can meet your specific size and quantity requirements.

8. Budget Considerations:

- Assess your project budget and evaluate the cost of the chosen 6061-T6 aluminum sheet.

- Balance material cost with the desired quality and performance.

9. Regulatory Compliance:

- Ensure that the selected aluminum sheet meets any regulatory or industry standards required for your project, especially in applications like aerospace or automotive.

10. Seek Expert Advice:

- If you’re uncertain about material selection, consult with engineers, metallurgists, or specialists who have experience with aluminum alloys and can provide guidance tailored to your project.

By following these steps and carefully considering your project’s requirements, you can make an informed decision when choosing 6061-T6 aluminum sheet that best suits your needs, ensuring a successful and durable outcome for your project.

The Reasons for Choosing Us

- Quality: We prioritize high-quality products and services to meet your needs effectively.

- Experience: With years of experience, we bring expertise to every project.

- Reliability: You can count on us for consistency and dependability.

- Innovation: We stay at the forefront of industry trends and technologies.

- Customization: Tailoring solutions to your unique requirements is our specialty.

- Customer Focus: Your satisfaction is our top priority, and we value your feedback.

- Competitive Pricing: We offer competitive rates without compromising on quality.

- Timely Delivery: We strive to meet deadlines and ensure projects stay on schedule.

- Transparency: Honesty and open communication are central to our business.

- Commitment: We are dedicated to delivering results that exceed your expectations.

These reasons showcase our dedication to providing top-notch products and services to our customers.