Specification

| Property | Value |

|---|---|

| Alloy Type | 3003 |

| Temper | H14, H16, H18, H22, H24, or custom temper |

| Thickness | Varies (0.2-10.0mm) |

| Width | Varies (typically up to 48″ or 1219.2 mm) |

| Length | Varies (typically up to 144″ or 3657.6 mm) |

| Density | 2.73 g/cm³ |

| Tensile Strength | 17,000 – 30,000 psi |

| Yield Strength | 13,000 – 24,000 psi |

| Elongation at Break | 20 – 40% |

| Modulus of Elasticity | 10.2 x 10^6 psi |

| Thermal Conductivity | 190 W/m·K |

| Electrical Conductivity | 35% IACS |

| Melting Point | 655°C (1,209°F) |

| Hardness (Brinell) | 40 – 55 |

| Machinability | Good |

| Weldability | Excellent |

| Corrosion Resistance | Excellent (especially in marine environments) |

| Formability | Very Good |

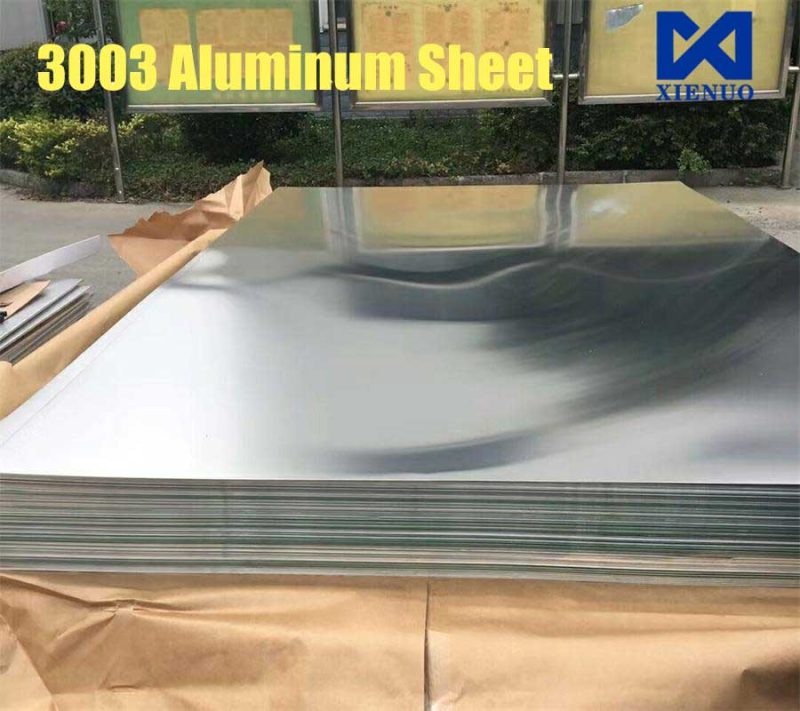

| Finish | Mill finish, brushed, or painted |

As with any material, specific properties of 3003 aluminum sheet may vary depending on the temper, thickness, and manufacturing process. Be sure to consult the manufacturer’s data sheets and specifications for precise information tailored to your project’s needs.

Details of 3003 Aluminum Sheet

| Element | Percentage Composition |

|---|---|

| Silicon (Si) | 0.0 – 0.6% |

| Iron (Fe) | 0.0 – 0.7% |

| Copper (Cu) | 0.05 – 0.20% |

| Manganese (Mn) | 1.0 – 1.5% |

| Magnesium (Mg) | 0.0 – 0.1% |

| Chromium (Cr) | 0.0 – 0.10% |

| Zinc (Zn) | 0.0 – 0.10% |

| Titanium (Ti) | 0.0 – 0.10% |

| Other Elements | 0.05% each, 0.15% total max |

| Aluminum (Al) | Remaining balance |

3003 aluminum sheet is a versatile alloy that offers several features, uses, and advantages, making it popular in various industries. Here’s a description of its key characteristics:

Features:

- Corrosion Resistance: One of the standout features of 3003 aluminum is its exceptional corrosion resistance. It is particularly resistant to atmospheric corrosion and is often used in marine and coastal applications.

- Formability: 3003 aluminum is highly formable, which makes it easy to bend, shape, and work into various configurations. It’s often used for applications requiring intricate shapes.

- Weldability: This alloy has good weldability, making it suitable for joining with various welding techniques, including TIG and MIG welding.

- Moderate Strength: 3003 aluminum offers moderate strength, making it appropriate for applications where strength is important but not critical.

- Non-Heat Treatable: Unlike some other aluminum alloys, 3003 is non-heat treatable. Its properties are primarily determined by cold working and strain hardening.

Uses:

- Cookware: Due to its excellent formability and resistance to corrosion, 3003 aluminum is commonly used for making cookware like pots, pans, and baking sheets.

- Construction: It is used in construction applications, including roofing, gutters, and siding, where corrosion resistance is crucial in harsh outdoor environments.

- HVAC Systems: 3003 aluminum is used in heating, ventilation, and air conditioning (HVAC) systems, including evaporator and condenser coils, because of its corrosion resistance and formability.

- Electrical Enclosures: The alloy is suitable for electrical enclosures and junction boxes due to its electrical conductivity and resistance to corrosion.

- Signage: It is used for signage and nameplates, where it can be easily formed and engraved.

- General Sheet Metal Work: 3003 aluminum is employed in various sheet metal applications, including automotive panels, lampshades, and appliance parts, thanks to its formability and corrosion resistance.

Advantages:

- Corrosion Resistance: 3003 aluminum’s outstanding corrosion resistance makes it ideal for outdoor and marine applications, reducing maintenance and replacement costs.

- Formability: Its exceptional formability allows for the creation of complex shapes and intricate designs, making it a versatile material.

- Weldability: The alloy’s good weldability simplifies fabrication processes and allows for the assembly of multi-component structures.

- Cost-Effective: 3003 aluminum is often more cost-effective than higher-strength alloys, making it an economical choice for various applications.

- Lightweight: Aluminum is inherently lightweight, which contributes to fuel efficiency in transportation applications and ease of handling.

- Recyclability: Aluminum is fully recyclable, making it an environmentally friendly choice with a low environmental impact.

3003 aluminum sheet is favored for its corrosion resistance, formability, and versatility, making it suitable for a range of applications in industries such as construction, automotive, cookware, and more. Its cost-effectiveness, ease of fabrication, and recyclability further enhance its appeal as a material choice.

How Much Does 3003 Aluminum Sheet Cost Per Kilogram

The price of Xienuo manufacturer’s aluminum plates is about US$2.0-3.8 per kilogram. The simple calculation method is the price of one kilogram of aluminum ingots plus the processing cost per kilogram. The price of aluminum plates is affected by the price fluctuation of aluminum ingots and processing costs, and will also follow changes in market conditions.

How to Choose 3003 Aluminum Sheet for Your Project

Choosing the right 3003 aluminum sheet for your project involves considering several factors to ensure it meets your specific needs and requirements. Here’s a step-by-step guide on how to make an informed selection:

1. Define Your Project Requirements:

- Clearly outline the purpose and function of the 3003 aluminum sheet in your project.

- Consider factors such as size, thickness, and specific properties needed (e.g., corrosion resistance, formability, strength).

2. Determine the Alloy and Temper:

- Confirm that 3003 is the appropriate alloy for your application, considering its corrosion resistance and formability.

- Choose the temper (e.g., H14, H16, H18) based on the desired hardness and formability. Each temper offers different mechanical properties.

3. Select Thickness and Dimensions:

- Measure or calculate the required thickness and dimensions of the aluminum sheet based on your project’s design and structural requirements.

4. Consider Surface Finish:

- Decide if you require a specific surface finish, such as mill finish, brushed, or painted, based on your project’s aesthetic and functional needs.

5. Check Alloy Purity:

- Ensure that the aluminum sheet is indeed 3003 alloy and not a different aluminum alloy.

- Verify if any specific alloy purity requirements are necessary for your project.

6. Assess Corrosion Resistance:

- Evaluate the environmental conditions the aluminum sheet will face (e.g., exposure to moisture, chemicals) and confirm that 3003’s corrosion resistance meets your needs.

7. Review Supplier Options:

- Research reputable aluminum suppliers and manufacturers.

- Compare prices, lead times, and available services, such as cutting or custom fabrication.

- Ensure that the supplier can meet your specific size and quantity requirements.

8. Budget Considerations:

- Assess your project budget and evaluate the cost of the chosen 3003 aluminum sheet. Consider any additional processing costs if required.

9. Regulatory Compliance:

- Ensure that the selected aluminum sheet meets any regulatory or industry standards relevant to your project, especially if it’s for specialized applications.

10. Seek Expert Advice:

- If you are uncertain about material selection, consult with engineers, metallurgists, or specialists who have experience with aluminum alloys and can provide guidance tailored to your project.

3003 Aluminum Sheet vs 6061 Aluminum Plate

| Property | 3003 Aluminum Sheet | 6061 Aluminum Plate |

|---|---|---|

| Alloy Type | 3003 | 6061 |

| Typical Temper | H14, H16, H18, H22, H24 | T6, T651, T6511, T4 |

| Corrosion Resistance | Excellent | Good |

| Strength | Moderate | High |

| Formability | Excellent | Good |

| Weldability | Excellent | Good |

| Machinability | Fair | Good |

| Heat Treatment | Non-Heat Treatable | Heat Treatable |

| Typical Uses | Cookware, roofing, HVAC, | Aerospace, automotive, |

| signage, general sheet | structural components, | |

| metal, electrical | marine, architectural | |

| enclosures | applications, | |

| general engineering |

3003 Aluminum Sheet:

- Corrosion Resistance: 3003 aluminum sheet offers excellent corrosion resistance, making it a suitable choice for outdoor and marine applications where exposure to moisture and corrosive elements is a concern.

- Strength: It provides moderate strength, which is adequate for applications where structural strength is not the primary requirement.

- Formability: 3003 aluminum is highly formable, allowing it to be easily bent, shaped, and worked into intricate designs, making it ideal for applications requiring complex forms.

- Weldability: This alloy is known for its excellent weldability, making it easy to join with various welding techniques, including TIG and MIG welding.

6061 Aluminum Plate:

- Corrosion Resistance: While 6061 aluminum plate offers good corrosion resistance, it may not be as corrosion-resistant as 3003 in highly corrosive environments. However, it is still suitable for a wide range of applications.

- Strength: 6061 aluminum is characterized by its high strength, making it a preferred choice for applications where structural integrity and load-bearing capacity are essential.

- Formability: It has good formability but may not be as easily formed into intricate shapes as 3003 aluminum due to its higher strength.

- Weldability: While 6061 aluminum can be welded, it may require more specialized welding techniques and filler materials compared to 3003 aluminum.

- Heat Treatment: 6061 is heat-treatable, allowing for further enhancement of its mechanical properties, including strength and hardness, through heat treatment processes.

In summary, the choice between 3003 aluminum sheet and 6061 aluminum plate depends on your specific project requirements. If you need excellent corrosion resistance, formability, and weldability, 3003 aluminum sheet is a suitable option.

Reasons for Choosing Xienuo’s 3003 Aluminum Plate

- High-Quality Materials: Xienuo’s 3003 aluminum plates are made from top-grade materials, ensuring excellent durability and performance.

- Precision Manufacturing: Our products are manufactured with precision and strict quality control to meet industry standards.

- Customization: We offer a range of sizes and thicknesses, as well as customization options, to suit your specific project needs.

- Corrosion Resistance: Xienuo’s 3003 aluminum plates are known for their exceptional corrosion resistance, making them ideal for various environments.

- Formability: These plates are highly formable, allowing for easy shaping and fabrication, which is essential for complex projects.

- Weldability: Our 3003 aluminum plates have excellent weldability, ensuring ease of assembly and construction.

- Competitive Pricing: We offer competitive pricing without compromising on quality, providing value for your investment.

- Wide Range of Applications: Xienuo’s 3003 aluminum plates are versatile and suitable for numerous applications across industries.

- Reliability: We prioritize reliability in product delivery, ensuring your project stays on schedule.

- Customer Satisfaction: Our focus is on your satisfaction. We value your feedback and strive to exceed your expectations in both product quality and service.