Specification

| Parameter | Description |

|---|---|

| Material | Aluminum |

| Alloy | Common alloys like 3003, 6061, 5052, etc. |

| Thickness | Typically 0.025 inches (0.63mm) to 0.125 inches (3.18mm) |

| Size | 4 feet (48 inches) by 8 feet (96 inches) |

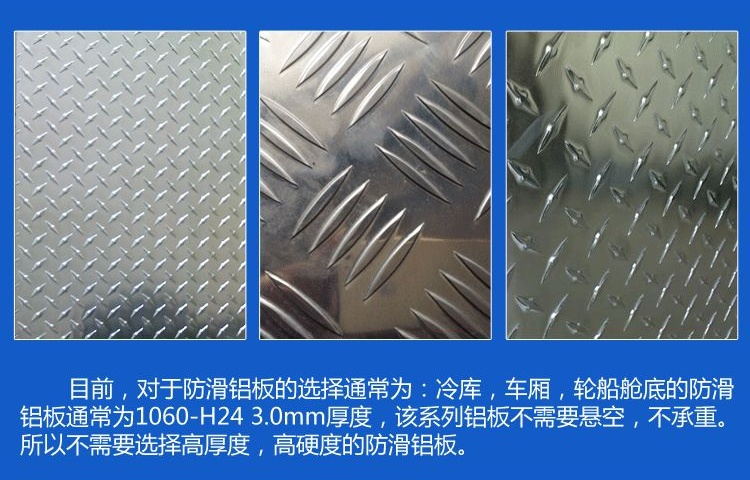

| Surface Finish | Diamond pattern embossed on one side |

| Weight per Square Foot | Approximately 1.25 pounds (0.57 kg) |

| Weight per Sheet | Varies based on thickness and alloy |

| Tensile Strength | Depends on the alloy and temper |

| Corrosion Resistance | High |

| Weldability | Good, with appropriate precautions |

| Machinability | Varies based on alloy |

| Common Uses | Flooring, wall cladding, decorative applications, trailers, garages, industrial settings, and more |

| Availability | Widely available through suppliers |

| Customization Options | Available for thickness, alloy, and surface finish |

| Sustainability | Recyclable and eco-friendly manufacturing options available |

Please note that the specific parameters may vary based on the supplier and the grade of 4×8 Aluminum Diamond Plate you choose, so it’s essential to consult with the supplier for precise details regarding the product you intend to purchase.

Applications

4×8 aluminum diamond plate1 is a versatile material with a distinctive diamond pattern embossed on one side. Its unique characteristics make it suitable for various applications across different industries. Here are some common uses for 4×8 aluminum diamond plate:

- Flooring: One of the primary applications is as durable and non-slip flooring in commercial vehicles, trailers, industrial settings, and even residential garages. The diamond pattern provides excellent traction and helps prevent slips and falls.

- Wall Cladding: The aesthetic appeal of aluminum diamond plate makes it a popular choice for wall cladding in both industrial and interior design settings. It adds a modern and industrial look to spaces while offering protection against wear and tear.

- Decorative Applications: Its unique texture and shine make it a favorite material for decorative projects. It’s often used for interior design elements, such as backsplashes, cabinet facing, and trim, giving spaces a contemporary and industrial feel.

- Toolboxes and Truck Bed Liners: Its ruggedness and resistance to corrosion make it suitable for fabricating toolboxes, truck bed liners, and other protective equipment. It can withstand heavy loads and harsh weather conditions.

- Stairs and Walkways: The non-slip surface of aluminum diamond plate is ideal for stairs, walkways, ramps, and platforms. It ensures safety in areas with heavy foot traffic.

- Trailers: Aluminum diamond plate is a popular choice for the exterior cladding of trailers. Its durability and resistance to corrosion make it ideal for protecting the trailer from road debris and environmental elements.

- Signage: Its reflective properties and durability make it suitable for outdoor signs. The diamond pattern can also add a unique visual element to signs.

- Industrial Applications: In industrial settings, it’s used for protecting equipment, machinery, and walls from damage due to forklifts, heavy traffic, and impact.

- Automotive Accessories: It’s commonly used to fabricate automotive accessories like running boards, fender trim, and mud flaps, enhancing the appearance and functionality of vehicles.

- Aerospace: In the aerospace industry, lightweight aluminum diamond plate is used for flooring, storage, and equipment surfaces in aircraft and aerospace vehicles.

- Marine Applications: Its resistance to corrosion makes it suitable for marine applications like boat decks, hull cladding, and gangways.

- Food Service: In commercial kitchens and food processing facilities, it’s used for worktables, countertops, and wall coverings due to its easy-to-clean surface and resistance to food acids.

Advantages of 4×8 aluminum tread plate

4×8 aluminum tread plate, with its unique properties and design, offers several advantages that make it a preferred choice in a wide range of applications. Here are some of the key advantages:

- Durability: Aluminum diamond plate is highly durable and resistant to wear and tear, making it ideal for applications that require a long-lasting and rugged material. It can withstand heavy loads and high traffic.

- Non-Slip Surface: The raised diamond pattern on one side of the plate provides excellent traction, making it a safe choice for flooring and walkways, especially in areas prone to moisture or oil.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, which gives it excellent corrosion resistance. This property makes it suitable for both indoor and outdoor applications, even in harsh environments.

- Lightweight: Aluminum is a lightweight material compared to steel, which makes it easier to handle and install. This advantage is particularly important in applications where weight is a concern, such as in the transportation industry.

- Aesthetic Appeal: The diamond pattern and the reflective surface of aluminum diamond plate provide an attractive, modern, and industrial appearance. It adds a unique visual element to various projects and spaces.

- Low Maintenance: Aluminum diamond plate is easy to clean and maintain. It resists staining, rusting, and discoloration, reducing the need for frequent cleaning or upkeep.

- Versatility: It’s a versatile material with a wide range of applications across industries, from automotive to construction, marine to aerospace. It can be used for both functional and decorative purposes.

- Weather Resistance: Aluminum diamond plate can withstand exposure to the elements, including rain, snow, and UV rays, without deteriorating or losing its structural integrity.

- Recyclability: Aluminum is highly recyclable, making it an environmentally responsible choice. Recycled aluminum retains its quality and properties, reducing the demand for primary aluminum production.

- Customization: Aluminum diamond plate can be customized to meet specific project requirements. This includes variations in thickness, alloy, and surface finish, allowing for tailored solutions.

- Cost-Effective: While aluminum can have a higher upfront cost compared to some other materials, its long lifespan, low maintenance, and durability often result in cost savings over the long term.

- Safety: The non-slip surface of aluminum diamond plate enhances safety in areas prone to slips and falls, reducing the risk of accidents.

- Reflectivity: The reflective surface can help improve visibility in low-light conditions, making it a suitable material for signs and safety applications.

Overall, 4×8 aluminum tread plate’s combination of strength, durability, safety features, and aesthetic appeal makes it a versatile and valuable material for a wide range of industrial, commercial, and residential applications.

How is aluminum diamond plate made?

Aluminum diamond plate, also known as tread plate or checker plate, is manufactured through a process called rolling and embossing2. Here’s an overview of how aluminum diamond plate is made:

- Material Selection: The process begins with the selection of high-quality aluminum sheet material. The choice of alloy and thickness can vary depending on the specific application and desired properties of the diamond plate.

- Cleaning and Pre-Treatment: The aluminum sheets are thoroughly cleaned and pre-treated to remove any surface contaminants, oxidation, or impurities. This step is crucial to ensure good adhesion of the protective coating.

- Rolling: The cleaned and pre-treated aluminum sheets are then passed through a rolling mill. During the rolling process, the sheets are gradually reduced in thickness and elongated in length. This step helps achieve the desired thickness and mechanical properties of the diamond plate.

- Annealing (Optional): In some cases, an annealing process may be used to soften the aluminum sheets, making them more malleable for the subsequent embossing process. This step is optional and depends on the specific alloy and desired characteristics of the diamond plate.

- Embossing: The distinctive diamond pattern is created through an embossing process. The aluminum sheet passes through a series of embossing rollers that have a raised diamond-shaped pattern on them. As the sheet passes through these rollers, the pattern is pressed into the surface of the aluminum, creating the raised diamond texture on one side.

- Trimming and Cutting: After embossing, the aluminum sheet is trimmed to the desired size and shape. This step ensures that the finished diamond plate meets the specified dimensions and requirements.

- Surface Finish: Depending on the intended use and appearance, the aluminum diamond plate may undergo additional surface treatments. This can include processes like polishing, coating, or anodizing to enhance its appearance and provide additional protection against corrosion.

- Quality Control: Throughout the manufacturing process, quality control measures are in place to check the thickness, pattern consistency, and overall quality of the diamond plate. Any defects or irregularities are identified and addressed.

- Packaging: Once the aluminum diamond plate has been manufactured and inspected, it is typically cut into sheets of standard sizes and packaged for distribution. Proper packaging ensures that the diamond plate reaches customers in excellent condition.

About Xienuo Aluminum

Henan Xienuo Aluminum is a comprehensive modern enterprise specializing in the sales and transportation of non-ferrous metals. The products are exported to the Middle East, Singapore, Malaysia, Thailand, Vietnam, Philippines, Indonesia and other regions, and have been well received and trusted by the majority of users.

The company’s main products include pure aluminum plates, alloy aluminum plates, aluminum coils, mirror aluminum plates, brushed aluminum plates, corrugated aluminum plates, orange peel embossed plates, five- and three-strip pattern plates, aluminum strips and various strips.

Since its establishment, the company’s products have been widely used in various fields such as industrial production, daily life, medical care, transportation, etc. It has provided high-quality products and perfect services to many well-known domestic and foreign enterprises, scientific research units, and road signage companies.

Henan Xienuo Aluminum adheres to the management philosophy of “being honest and doing things with integrity”, pursues high-quality products and excellent services, and strictly controls product quality. Our company has a professional sales and technical team.

In addition to supplying various series of standard plates, we can also customize non-standard plates of different series, different conditions and sizes according to customer needs.

Henan Xienuo Aluminum has won the trust and favor of many customers at home and abroad with its professional services, excellent technical strength, perfect operating procedures, and sufficient inventory. It has always been the preferred supplier of aluminum plate products for customers.

Contact Us Now

📩Email: admin@xienuoenterprise.com

or Leave a message online

Related Keyword List

4×8 diamond plate

diamond plate sheets 4×8 near me

diamond plate sheets 4×8

aluminum diamond plate sheets 4×8

black diamond plate sheets 4×8

aluminum checker plate 4×8

diamond plate aluminum sheets 4×8 home depot

aluminium checker plate 8×4

0.25 aluminum diamond plate 4×8 sheet

checker plate aluminium 4×8

4×8 aluminum diamond plate near me

4 by 8 sheet of diamond plate

025 aluminum diamond plate 4×8 sheet

4×8 sheet of 1 8 inch aluminum diamond plate

1 4 aluminum diamond plate 4×8

aluminum tread plate 4×8

1 8 aluminum diamond plate 4 x8

4 8 diamond plate sheets

4×8 1 8 diamond plate aluminum

diamond plate 4 x 8 sheets

4×8 checker plate aluminum

4×8 1 4 diamond plate aluminum

4×8 aluminum checker plate

4×8 3 16 aluminum diamond plate